Value Added Services (VAS)

Enhancing efficiency by Optimized Aero dynamics

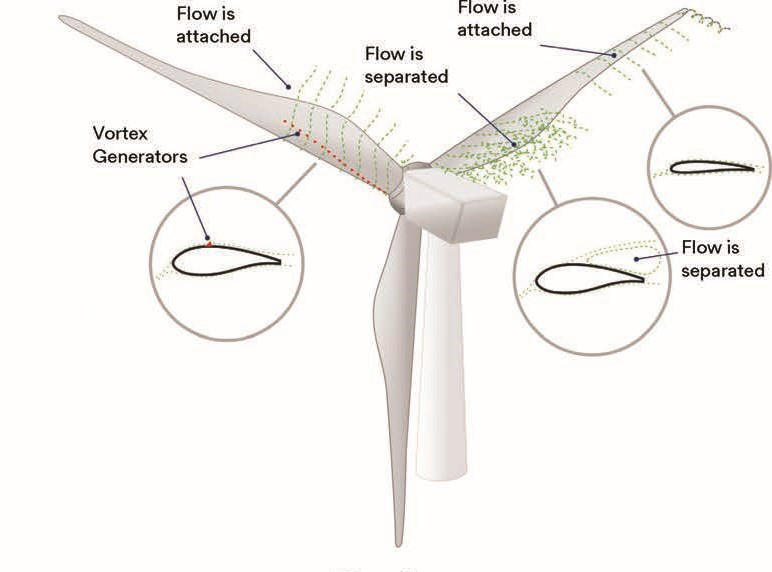

Due to shape and operation limitations, the blades of large pitch-regulated wind turbines often have suboptimal aerodynamic properties at the root. This frequently leads to an undesired airflow separation, known as aerodynamic stall and can have a significant negative impact on wind turbine efficiency. Surface roughness and leading edge erosion can only increase the problem

With 3M, We have signed an agreement to install Vortex Generators (VG’s) on WTGs in India. This collaboration will leverage the materials expertise and technology of 3M combined with the skills & competence of RENOM to provide asset owners a solution to increase efficiency and maximize Annual Energy Production to 1% or more from the wind turbines.

3M Wind Vortex Generators are attached to the root section of a wind turbine blade on spots that are determined using a proprietary analysis process. They help improve performance by energizing flow around the surface. This helps reduce flow separation and increases the performance of the entire turbine, in terms of power, loads and service life.

Increased efficiency

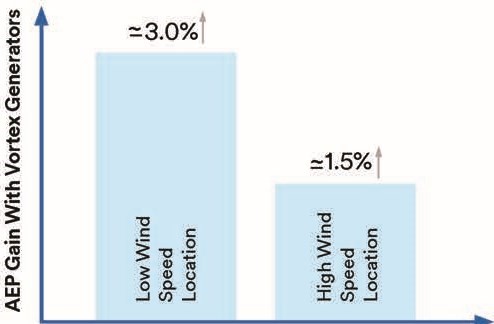

Increase of Annual energy production typically in the range of 1.5 to 3 % has been confirmed in different case studies, however this varies depends on turbine type , turbine conditions & site conditions .

Stabilized aerodynamics help balance load effects of unsteady wind conditions

Reduced noise due to less stall

Easy to Install and Faster Pay-back

Designed for higher reliability and fast roll out to wind parks

Qualified installation specialists

Adaptable to different blade types independent of turbine OEM

Proven in hundreds of existing installations and backed by case studies about actual performance improvement

Payback time of approximately 2 to 2.5 years including installation, materials and downtime

3M Wind Vortex Generators are attached to the root section of a wind turbine blade on spots that are determined using a proprietary analysis process. They help improve performance by energizing flow around the surface. This helps reduce flow separation and increases the performance of the entire turbine, in terms of power, loads and service life