Asset digitalization and Optimization

At RENOM, we have taken every effort to benchmark the global industry trends and the future needs of the customers. There is a constant effort on improving the service standards to enhance the turbines reliability, performance and sustainability. With digitization, RENOM is able to better leverage analytics to improve operational efficiency and predictive maintenance. The digitization journey of RENOM has evolved from the yesterday’s SCADA until the tomorrow’s world of Digital Twin with Augmented and Virtual reality

SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

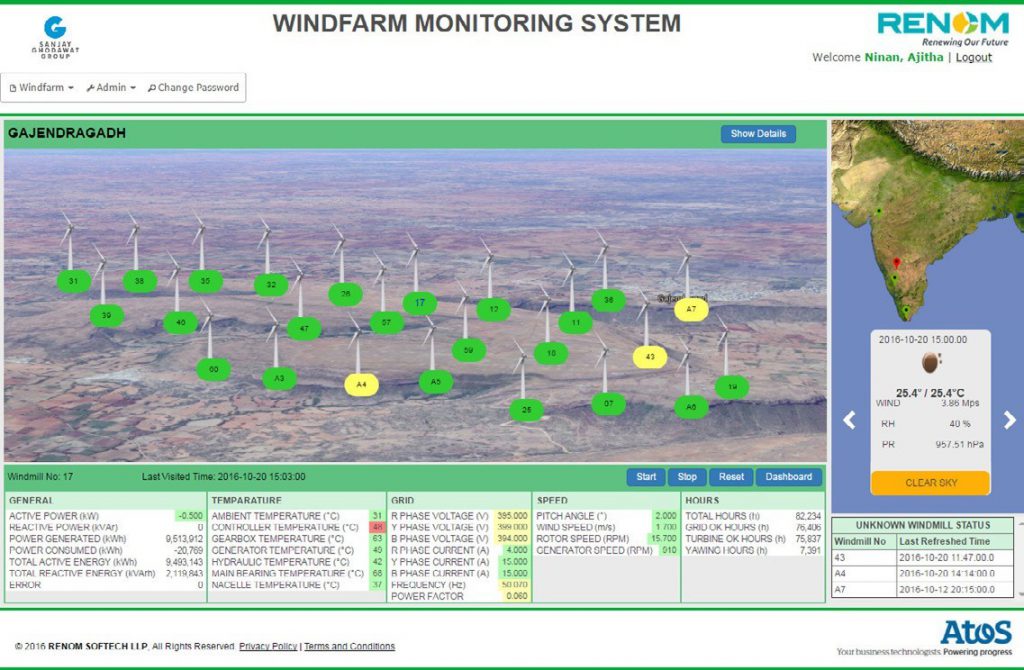

RENOM with our big data partner ATOS have jointly developed ONE SCADA (supervisory control and data acquisition) solution to provide visibility, remote monitoring, diagnostics to help customers and O&M service providers effectively utilize available resources to manage power generation at optimal levels.

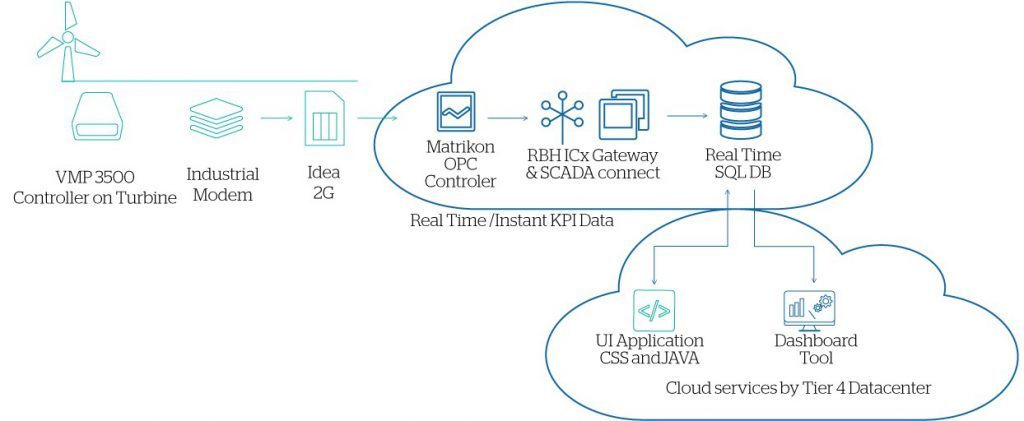

Architecture

- Cloud based solution to eliminate Capital IT Infrastructure cost and make Implementation & Data Integration much faster

- Vendor agnostic SCADA system on standard protocol with no dependency on OEMs

- Best in class technologies used to build solution

Real Time

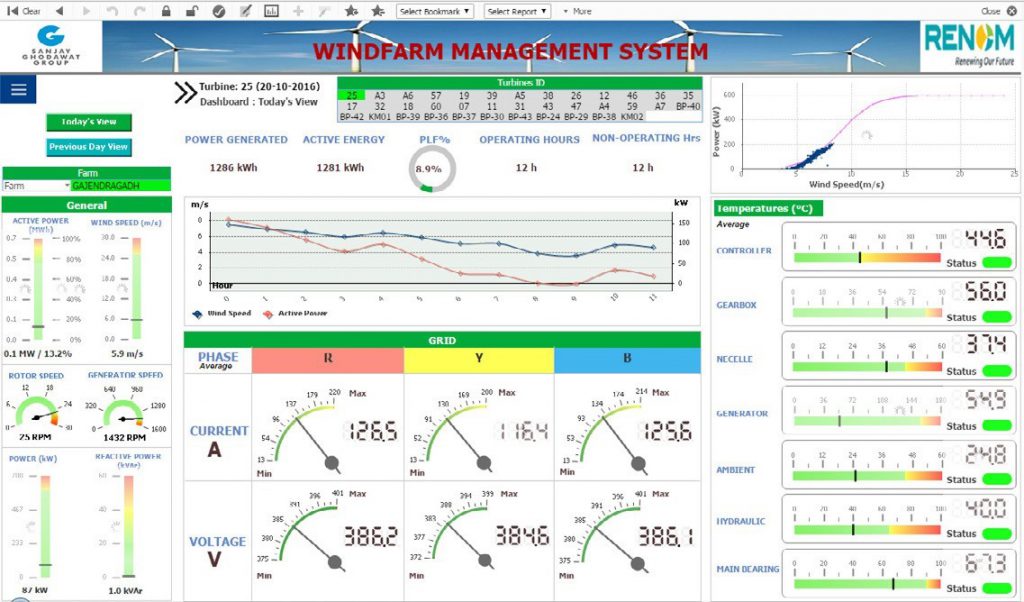

- Near Real time data analytics with Best in Class Analytics tool

- 40+ KPIs representation at Turbine & Windfarm levels for different Turbine makes on 1 dashboard

- Graphical representation of KPIs for effective operations management

- Real time views of Power curves, Daily Generation reports, PLF% etc.

- Slice and Dice capability zoom in on specific KPIs for Cause and Effect analysis

- Error and Event logs with parameter values integrated

- Historical data availability for further analytics

Data Analytics

- Real time interface with Turbines / Windfarm

- Best in class UX solution with high performance

- Remote controlling options for Turbine Start/Stop/ Reset with security layers

- Real time updates for Turbine Status, 32+ KPIs & Alerts

- Admin functions & Reporting

Integrated View

Integrated view of status of all Turbines being managed; anytime, any where

Automate Data

Automated data collection and thereby reduction in site operations staff.

Remote diagnostics

Remote diagnostics and remote controlling of Wind Turbines

Remote Monitoring

Remote monitoring facility will facilitate all stake holders visualize one set of data and decision making much easier

Integrated View

Best in class technology solutions used for building the solution (Matrikon OPC, Qlikview etc.)

SCADA

Solution offered is open system SCADA on standard protocol, with no dependency on OEMs

Scalable

This same SCADA can be used for Solar Plant and other Renewable Energy plants as well, making the solution highly scalable

Cloud

This same SCADA can be used for Solar Plant and other Renewable Energy plants as well, making the solution highly scalable

Vendor Agnostic

Solution is vendor Agnostic, meaning no dependency on controller and OEMs

Realistically achievable

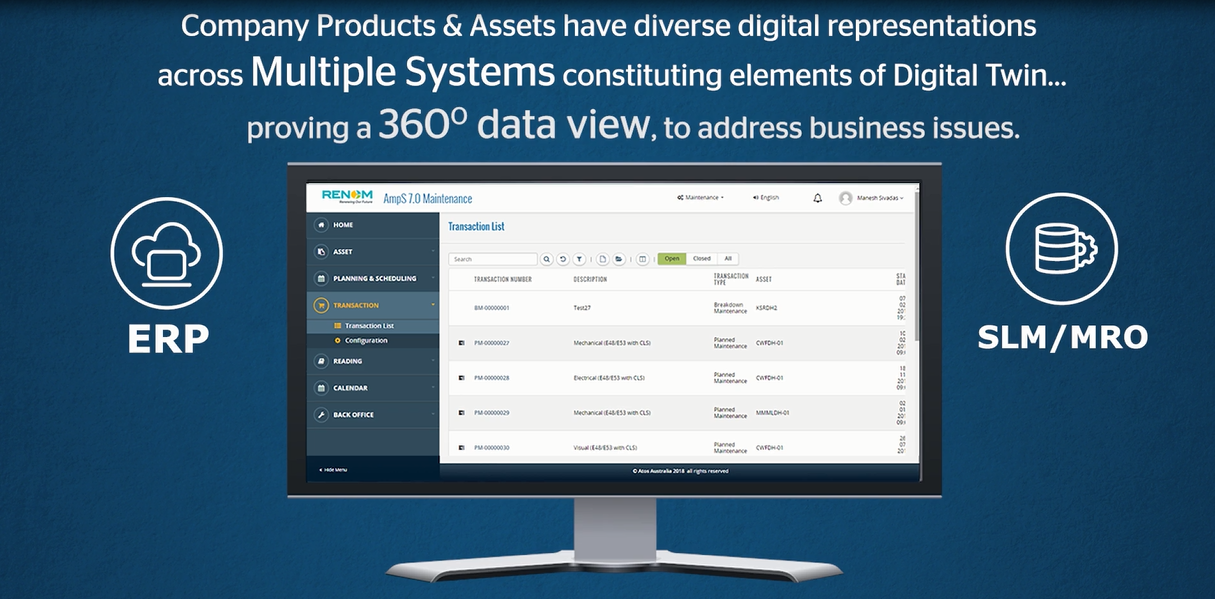

AMPS

AMPS stands for Asset Management Planning system. The Asset Management and Planning System (AMPS) from Atos is a proven way for complex industries to keep track of their assets. By allocating resources appropriately, AMPS enhances productivity at all levels, while minimizing operational costs.

In association with RENOM, ATOS has customized the AMPS solution exclusively to suit the needs for Wind turbine Operation and Maintenance Module. The system is capable of capturing and reporting all data pertaining to Preventive Maintenance, Break down maintenance, Defective component handling, Spares replacements, Monitoring of MTTR and MTBF, Machine availability, Cost of quality including dash board and Analytics for Management MIS.

Integrated with SCADA, AMPS could ensure there is not single aorta of data getting missed out for reporting as there is an auto-ticketing getting created in AMPS for Break down maintenance based on every fault captured in SCADA which makes this total solution very robust.

Digital Twins

A digital twin is an exact digital replica of a product, process or service. This living model creates a thread between the physical and digital world. Internet of things (IoT)-connected objects are replicated digitally, enabling simulations, testing, modeling, and monitoring based on the data collected by IoT sensors. Like everything in the realm of IoT, data is the primary driver, and most invaluable output, of digital twins. The sharing and analysis of digital twin data empower companies to make decisions which directly impact their key performance indicators.

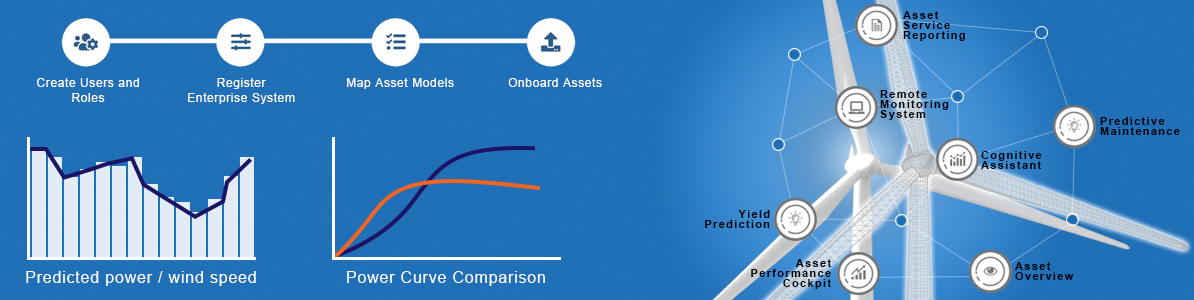

ATOS, the leading global big data company combined with the wind domain expertise of RENOM have successfully developed a DT platform for Wind turbine operations and maintenance. The DT fabric can integrate the diverse digital platforms of IOT, ERP, PLM, AMPS, SCADA providing a 360-degree view of the asset performance to make informed decisions.

Gains of using a Digital Twin in O&M

- Predicting the Remaining Useful Life (RUL) per turbine for only the component

- Yield prediction

- Reduce unscheduled downtime due to component failures by predicting components that are at risks